Quanterion publishes an electronic version of “Reliability Ques” periodically as a means of keeping its customers and other interested parties up-to-date on effective tools, techniques, and approaches to improving the reliability, maintainability, and quality of products and systems.

Reliability: Costly, or Cost Effective?

Reliability: Costly, or Cost Effective?

There are those who would argue that the costs of reliability activities associated with developing new products have little payoff. Whether we’re talking about commercial products or military systems, we don’t agree. Concepts like Life Cycle Costs, Total Ownership Costs, Reliability-based Maintenance, Performance-Based Logistics, and others clearly recognize the contribution of… Read More

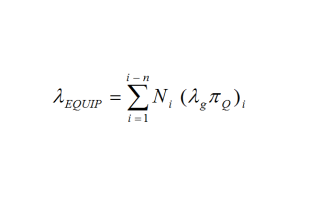

Reliability Predictions: Parts Count, Part Stress, Pseudo Stress and Dormant

Reliability Predictions: Parts Count, Part Stress, Pseudo Stress and Dormant

Reliability predictions are an important tool for making design trade-off decisions and estimating future system reliability. They are often used for making initial product support decisions such as how many spares are required to support fielded systems. Inaccurate predictions can lead to overly conservative designs and/or… Read More

Reliability Knowledge? Who? What? Where?

Reliability Knowledge? Who? What? Where?

This article is the first in a series addressing the availability of reliability knowledge, who has it and how you can take advantage of it to improve products and systems. Despite a broad interest in reliability, there is a general lack of coordination of the efforts of many disparate organizations dealing… Read More

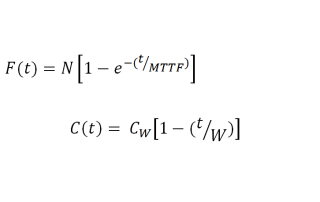

Warranty Cost: An Introduction

Warranty Cost: An Introduction

Whether your company is marketing commercial products or selling to the Government, warranties are an important ingredient to competitive success. Effective warranty planning can ensure success, but lack of attention to cost analyses can spell disaster. This article is intended to introduce the basics of warranties and to identify sources for more… Read More

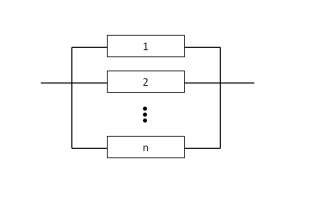

Understanding Your Product Through Reliability Modeling

Understanding Your Product Through Reliability Modeling

A reliability model represents a clear picture of your product’s functional interdependencies providing a means to trade-off design alternatives and to identify areas for design improvement. The models are also helpful in:

Identifying of critical items and single points of failure

Allocating reliability goals to portions of the design

Providing… Read More

How Much Reliability is Enough?

How Much Reliability is Enough?

Reliability is defined as performance of a function over time, whether it applies to a commercial product or a military system. Commercial product reliability is usually driven by such factors as warranty cost goals, competitive marketing strategies, and liability concerns while the military wants to meet the operational needs of users… Read More

System Spares – What’s the “Right” Answer?

System Spares – What’s the “Right” Answer?

Manufacturers are often faced with questions such as:

How often will my system fail?

How many spare parts should I stock?

How confident am I that I will have enough spare parts?

We recently had a customer that had to answer these and other questions pertaining to warranty and system… Read More

Using Accelerated Life Testing to Assess Warranty Risk

Using Accelerated Life Testing to Assess Warranty Risk

During a recent project, a question arose about the feasibility of providing a ten year warranty for a new system. The system consisted of a proven electronic assembly and 40 newly designed hybrid electronic modules. Warranty costs could be significant if reliability risks were not fully understood. The… Read More

Which Variables Are Critical to Field Reliability? Design of Experiments (DOE) Can Help Optimize Your Design

Which Variables Are Critical to Field Reliability? Design of Experiments (DOE) Can Help Optimize Your Design

Engineers are often faced with the problem of optimizing a process that includes a number of input variables. It could be an analysis of a manufacturing process, or even an analysis of a business process. They’re often challenged to find… Read More

Which Design is More Reliable? Weibull Provides Answers!

Which Design is More Reliable? Weibull Provides Answers!

Weibull Analysis is often used to analyze field or test failure data to understand how items are failing and what specific underlying failure distribution is being followed by failures that occur. One of our staff engineers was recently responsible for making a vendor recommendation for a limited life… Read More