Quanterion publishes an electronic version of “Reliability Ques” periodically as a means of keeping its customers and other interested parties up-to-date on effective tools, techniques, and approaches to improving the reliability, maintainability, and quality of products and systems.

How Good Is Your Reliability Approach?

How Good Is Your Reliability Approach?

Product reliability is an important discriminator in today’s global marketplace but does your organization know how it’s doing compared to competitors in terms of designing and building reliability into its products? Could/should you be doing more “upfront” reliability activities to improve customer satisfaction, to reduce warranty costs, and to reduce… Read More

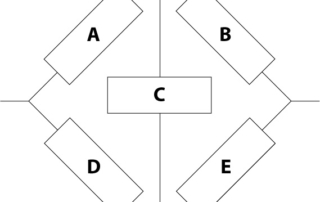

Solving the Complex RBD-Series Parallel System with a Keystone Component

Solving the Complex RBD-Series Parallel System with a Keystone Component

The general form of this type of reliability block diagram has two series circuits in a parallel arrangement combined through a center or “keystone” unit. You are often given the reliability of each block and asked to calculate the reliability of the circuit.

For example let’s say… Read More

Environmental Stress Screening: Basic Steps in Choosing an ESS Profile

Environmental Stress Screening: Basic Steps in Choosing an ESS Profile

Environmental Stress Screening (ESS) is the process of exposing a newly manufactured product to environmental stresses in order to identify and eliminate latent defects introduced during the manufacturing process. It is part of the manufacturing process and is therefore performed on 100% of the items manufactured.… Read More

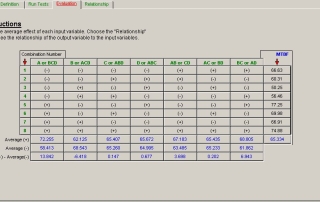

Design of Experiments for Reliability Improvement

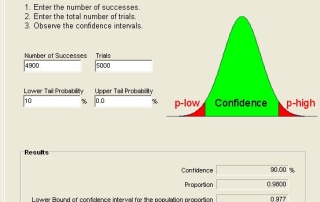

Test Samples: How Many Are Needed?

Test Samples: How Many Are Needed?

For demonstrating product reliability the question of how many test samples are needed to be “X” percent confident of having met a reliability objective often comes up. Let’s say that manufacturer is going to produce 5,000 rooftop car carriers and is willing to tolerate roughly 100 returns over the next… Read More

Need Technical Help? Try an IAC

Need Technical Help? Try an IAC

The IACs have been consolidated since this page was published. None of these IACs are currently in operation.

Last month we introduced you to the Department of Defense (DoD) Reliability Information Analysis Center (RIAC), formerly known as the Reliability Analysis Center (RAC), as a valuable resource for expertise and data/information in… Read More

Reliability Certification

Reliability Certification

Starting salaries for engineers graduating from college this spring will be in the $50K neighborhood and even higher for the top students, as well as those with specialized experience. The degrees are typically electrical, electronics, mechanical, materials, civil, industrial, computer, and so on. Seldom is there a “reliability engineering” graduate. There are a few… Read More

Mission Reliability and Logistics Reliability: A Design Paradox

Mission Reliability and Logistics Reliability: A Design Paradox

The goal of improving system reliability often presents a design paradox; “mission” reliability cannot be increased without simultaneously decreasing “logistics” reliability. When faced with the challenge of a system that has inadequate reliability to meet specification requirements, hardware redundancy is often implemented, leading to an improvement in one… Read More

Probability and Statistics for Reliability: An Introduction

Probability and Statistics for Reliability: An Introduction

Painful as it is to many of us, the generally desirable product characteristicReliability is heavily dependent on Probability and Statistics for measuring and describing its characteristics. This edition of Reliability Ques will only be the tip of the iceberg in this regard. Let’s start with a few basics:

Failure… Read More

Better Reliability Predictions Using Experience Data

Better Reliability Predictions Using Experience Data

There are many approaches that can be used to predict the reliability of an item. Sometimes when asked to provide a “quick estimate” of an item’s reliability, the use of field experience is overlooked, or if no failures have occurred, overly conservative estimates are made by assuming one failure. This… Read More