Quanterion publishes an electronic version of “Reliability Ques” periodically as a means of keeping its customers and other interested parties up-to-date on effective tools, techniques, and approaches to improving the reliability, maintainability, and quality of products and systems.

Lessons in System Reliability

Welcome to Lessons in System Reliability, a series of reliability engineering articles based on a popular guide, the System Reliability Toolkit-V: New Approaches and Practical Applications!

The important topics included in these short publications are shared here from the popular 900+ page System Reliability Toolkit-V by Quanterion Solutions. Please give us a call if you need… Read More

Pieces of Pi

Pieces of Pi

Welcome to a new reliability engineering tech brief series written by one of our in-house engineers!

“Pieces of Pi” is a new article series that explores the unique aspects of Reliability, Maintainability and Quality of certain forms of design. It is the author’s opinion that reliability and design practices are closely related. The inherent… Read More

Calculating an Average Infant Mortality Factor Over a Given Service Life Using the 217Plus™ Methodology

Calculating an Average Infant Mortality Factor Over a Given Service Life Using the 217Plus™ Methodology

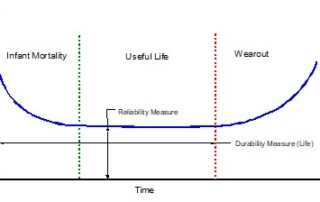

Infant mortality is a term that is often used to describe early-life failures – that is, failures that occur due to premature excitation of failure mechanisms. Such failures are typically due to inferior material (e.g., parts used in the manufacturing process… Read More

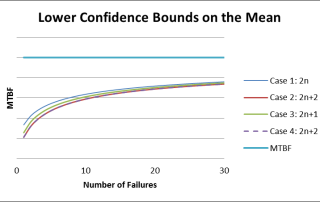

Confidence Bounds on the Mean Time Between Failure (MTBF) for a Time-Truncated Test

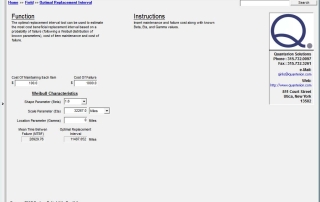

Maintenance Planning with Wearout Failure Modes

Maintenance Planning with a Constant Failure Rate

Maintenance Planning with Early Failures

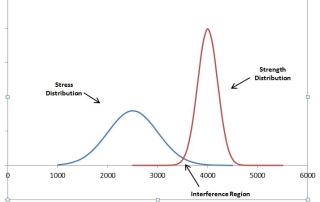

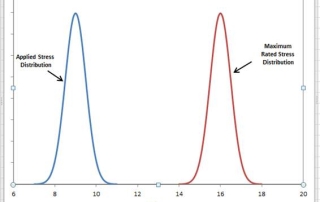

Interference Stress/Strength Analysis

Interference Stress/Strength Analysis

In simplest terms, an item fails when a stress to which it is subjected exceeds the corresponding strength. In this sense, strength can be viewed as “resistance to failure.” Good design practice is such that the strength is always greater than the expected stress. The safety factor “η” can be defined in terms… Read More

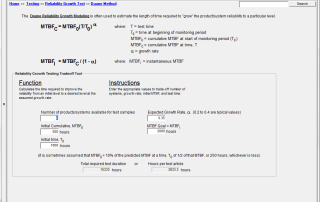

Models Commonly Used to Measure Reliability Growth

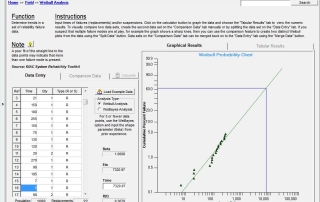

Models Commonly Used to Measure Reliability Growth

Reliability growth is the intentional positive improvement that is made in the reliability of a product or system as defects are detected, analyzed for root cause, and removed. The process of defect removal can be ad hoc, as they are discovered during design and development, a function of an… Read More